芯华章携仿真车验证方案出席国际集成电路产业汽车芯片分论坛

芯华章携仿真车验证方案出席国际集成电路产业汽车芯片分论坛

近期,2023中国·南沙国际集成电路产业论坛在广州盛大召开。作为国内领先的系统级验证EDA解决方案提供商,芯华章科技应邀出席“汽车芯片分论坛”,共同探讨汽车芯片产业的新机遇。芯华章科技汽车电子事业部首席算法科学家张磊博士受邀发表《场景+芯片仿真赋能个性化汽车芯片》的主题演讲,分享基于场景的系统级仿真对于主机厂构建自主可控“芯”生态的广阔应用场景。

Recently, the 2023 China·Nansha International Integrated Circuit Industry Forum was grandly held in Guangzhou. As a leading provider of system-level verification EDA solutions in China, X-EPIC was invited to attend the "Automotive Chip Sub-Forum" to discuss new opportunities in the automotive chip industry. Dr. Zhang Lei, Chief Algorithm Scientist of X-EPIC Automotive Electronics Division, was invited to deliver a keynote speech on "Scene + Chip Simulation Empowering Personalized Automotive Chips", sharing the importance of scenario- d system-level simulation for OEMs to build an independent and controllable "core" ecology broad applications.

张磊博士简介

About Dr. Zhang Lei

中科院计算所工学博士学位

武汉大学数学系本科

前SAS中国区首席科学家

TeraData&IBM近二十年算法和数据挖掘经验

He holds Ph.D. in Engineering from the Institute of Computing Technology, Chinese Academy of Sciences

Bachelor of Mathematics, Wuhan University

Former Chief Scientist of SAS China

He has nearly 20 years of experience in data algorithms and data mining in TeraData & IBM.

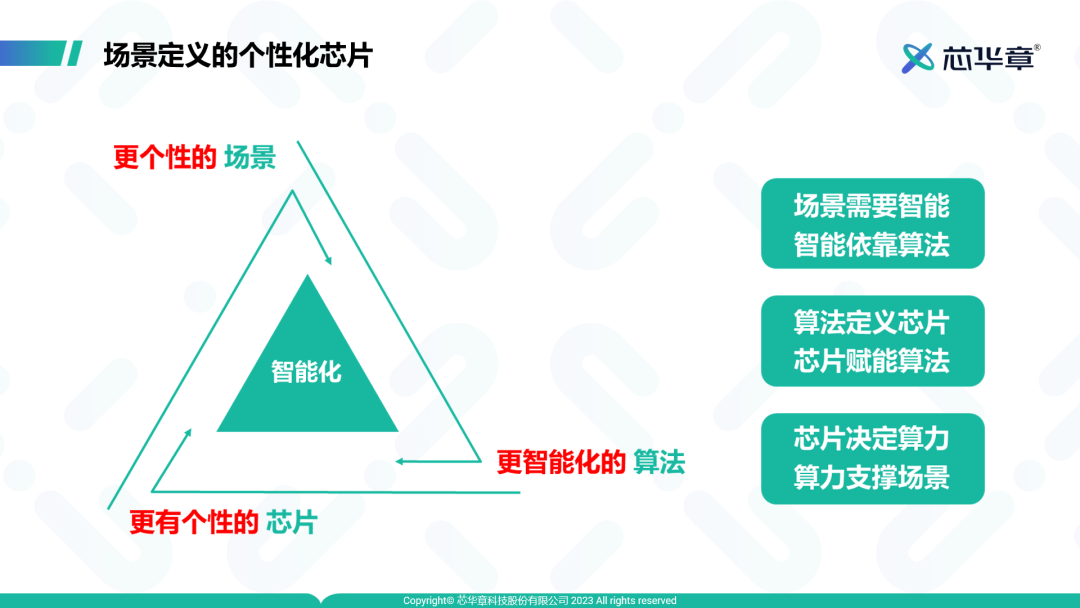

随着汽车产业新四化的演进,在智能化的下半场,主机厂与其产业配套供应商已经意识到,产品的功能和体验不仅仅依靠软件定义来实现,同时更加需要芯片定义的支持,才能在满足性能和安全性的同时,给用户提供具有更高性价比的方案与产品。

With the evolution of the New Four Modernizations of the automobile industry, in the second half of the intelligentization,both original equipment manufacturers (OEMs) and their industry suppliers have recognized that the functionality and user experience of products rely not only on software definition but also on chip definition. This support from chip definition is essential to provide users with solutions and products that offer higher cost-effectiveness while meeting performance and safety requirements.

在整车架构趋同、功能同质化严重的智能汽车时代,重“芯”构建生态,给车主带来更加个性化的场景体验,就需要更智能化的算法和超性价比系统方案。但是今天,一款车型的SOP大概需要36~48个月,芯片的开发周期也需要24~36个月。9成以上的在售新车型,都在用上一代芯片。让新车不再用“旧“芯片是芯华章仿真车希望赋能行业解决的核心问题。

In the era of smart cars with similar vehicle architectures and function homogeneity, more intelligent algorithms and super cost-effective system solutions are needed to focus on "core" to build an ecology and bring more personalized scene experiences to car owners. But today, the SOP of a car model takes about 36-48 months, and the chip delivery cycle also takes 24-36 months. More than 90% of the new models on sale are using the previous generation of chips. Making new cars no longer use "old" chips is the core problem that X-EPIC car simulation solution aims to solve.

2021年6月10日,芯华章正式发布了《EDA 2.0白皮书》。

June 10, 2021, X-EPIC officially released "EDA 2.0 White Paper"

芯华章科技董事长兼CEO王礼宾:

Mr. Wang Libin, Chairman and CEO of X-EPIC

智能化的EDA 2.0时代,会使设计芯片像开发程序那样简单,制造芯片像搭积木那样灵活,这个未来并不遥远,技术已经在路上,芯华章有信心让EDA 2.0诞生在中国,诞生在离未来最近的地方。

In the era of intelligent EDA 2.0, designing chips will be as simple as software programing, manufacturing chips are as flexible as building legos, this future is not far away, the technology is already on the way, X-EPIC is confident in bringing about the birth of EDA 2.0 in China, right at the forefront of the future.

深耕汽车电子产业,芯华章对EDA 2.0践行和突破。在芯华章的仿真车解决方案中,借助自主研发的高性能硬件仿真系统HuaEmu E1:

用户能够针对不同的应用场景,来预判车辆在实际使用过程中出现的风险;

实现软硬件的开发解耦和前置,帮助主机厂缩短研发周期;

降低学习门槛,丰富开发工具的同时优化硬件设计;

更快进阶到个性化定义EEA系统,缩短产品上市时间,在激烈的市场竞争中赢得先机

Deeply cultivating in the automotive electronics industry is the practice and breakthrough of X-EPIC's EDA 2.0. In X-EPIC's car simulation solution, with the help of the self-developed high-performance emulation system HuaEmu E1:

Users can predict the risks of vehicles in actual use for different scenarios.

Decouple of software and hardware development from early on, help OEMs shrink the R&D cycle.

Flatten the learning curve, enrich the development tools and optimize the hardware design.

Advance to the customized definition of the EEA system, shorten the time to market, and take the leading position in new market competition.

目前,芯华章的仿真车解决方案,已经率先在国内头部主机厂和Tier1方案上中得到突破性尝试。智己汽车整车研发中心副总工程师兼架构及整车集成部总监康飞表示:

在车规芯片的应用、测试过程当中,需要与搭载的软件提前进行配合,才能够降低芯片在整车应用过程中的风险,确保低故障的同时,又能够让芯片的性能真正的发挥。

一款优秀的场景和芯片仿真验证工具,可以帮助解决时间、人才、工具等三方面的挑战,更快地进行定制化芯片的研发,降低开发人才门槛,缩短开发周期,降低各项风险。

芯片和应用软件的协同开发是未来汽车领域产品差异化及提升用户体验的关键点之一,借助强大的仿真、定义、验证工具,能够帮助产品实现更好的差异化,从而为用户提供更高性价比的产品。

At present, X-EPIC's car simulation solution has taken the lead in making breakthrough attempts in domestic head OEMs and Tier1 solutions. Kang Fei, Deputy Chief Engineer and Director of Architecture and Vehicle Integration Department at Zhiji Automotive Research and Development Center says:

In the application and testing process of automotive-grade, it is necessary to coordinate with the ded software in advance in order to reduce risks during the chip's integration into the vehicle system. This ensures both low failure rates and the optimal performance of the chip.

An excellent scenario and chip simulation verification tool can help address challenges in terms of time, talent, and tools. It enables faster development of customized chips, reduces the talent threshold for development, shortens the development cycle, and mitigates various risks.

The collaborative development of chips and application software is one of the key factors for product differentiation and improving user experience in the future automotive industry. With powerful simulation, definition, and verification tools, products can achieve better differentiation, thus providing us with higher cost-effective solutions.

芯华章先进的系统级场景仿真平台和协同验证平台,帮助汽车电子加快下一代电子电气架构的“芯”迭代,赋能客户构建“芯”生态,掌握“芯”动力。

X-EPIC's advanced system-level scenario simulation platform and collaborative verification platform, help automotive electronics accelerate the "core" iteration of the next-generation electrical and electronic architecture, empowering customers to create an "SoC" ecosystem and harness the full potential of "SoC" technology.

我要收藏

个赞

评论排行